Maximizing Airfield Safety: How Often Should You Be FOD Sweeping?

Airfields are a critical part of the aviation industry, and ensuring they are as safe as possible is essential. One of the most effective ways to do...

5 min read

Aerosweep

:

Oct 19, 2022 12:24:31 PM

Aerosweep

:

Oct 19, 2022 12:24:31 PM

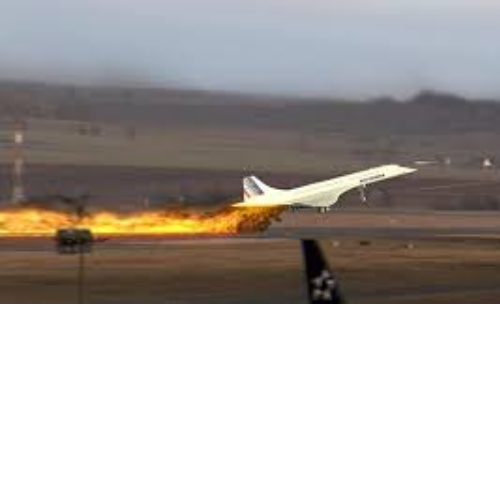

Removing foreign object debris (FOD) from its four runways, 18 major taxiways, ramps and other airfield areas is a constant priority for the Tennessee airport. Last year alone, crews removed nearly 400 pieces of FOD, thus preventing the items from being ingested into aircraft engines and causing costly damage. Between aircraft repairs and related downtime, FOD is estimated to cost the global aerospace industry $4 billion to $10 billion per year.

Like other airports, MEM focuses on training, detection, removal and prevention, according to guidance from the FAA Office of Airports. “But every airport is unique,” notes Glen Thomas, MEM’s director of Strategic Marketing and Communications.

As the world’s second busiest cargo airport, much of MEM’s traffic occurs between 10 p.m. and 4 a.m. “That translates into a lot of aircraft, vehicle, service equipment and personnel activity in the dark, where materials can escape unseen,” explains Terry Blue, vice president of Operations with the Memphis-Shelby County Airport Authority. “It also means a lot of package sorting. And no matter how good a tenant’s mitigation program is, as is the case here in Memphis, it still creates the potential for FOD. That means the Operations team must remain ever-vigilant.”

Not surprisingly, crews encounter extra plastic wrap, Styrofoam and cardboard on the airfield when cargo traffic increases during the holiday season. In warmer months, however, they are more attuned to grass clippings blowing onto runways and other critical operating areas, because they can potentially make pavement slippery and also attract wildlife such as geese.

Given MEM’s particular traffic, it goes above and beyond minimum FAA requirements for at least one airfield inspection per day. Instead, the Operations department typically performs three every day, one per shift. Crews also execute different types of inspections and vary the routes they take. “This helps cut down on complacency and helps ensure that inspectors can view surfaces from multiple directions,” explains Jarin Horton, manager of Operations with the Airport Authority.

Beyond their regular daily inspections, crews make additional checks during construction projects and other events that could increase the likelihood of FOD. “Meteorological conditions may also affect safe air carrier operations, such as a lightning strike causing a pavement break out,” says Horton.

Usually, nine of MEM’s 11 Operations employees are directly involved in clearing and preventing FOD. But once a year, the crew expands dramatically when all 63 full-time Airfield Maintenance employees join the Ops team to conduct a safety walk.

Preventive Measures

In addition to searching for and removing FOD, the airport actively works to prevent it in the first place.

The installation of fencing on the north side of the airfield has helped stop trash from blowing onto critical operating areas. And MEM holds monthly safety meetings with airlines and other tenants. “We try to pinpoint where FOD is coming from,” Horton explains. “It may be as simple as making sure a trash bin lid is on.”

The airport scored a significant proactive win a number of years ago after crews began noticing stray fuel caps on runways and taxiways. Operations personnel started tracking what caps were found where, and prepared a report they shared with the FAA, Transport Canada and Airbus. “None of the original Airbus-designed fuel caps were found on movement areas; the problem was only aftermarket fuel caps used by some carriers on Airbus equipment,” stresses Operations Duty Manager Dave Moreau. “The caps in question were believed to present problems for fuelling agents if reattached incorrectly.”

After receiving the report from MEM’s Operations Department, Airbus issued a Service Information Letter in 2004 and Transport Canada issued a Service Difficulty Advisory in 2007.

“Since these documents were published, we have only found one fuel cap,” reports Moreau. “This single find may have been lost in an infield area prior to the resolutions and training adopted by fuellers following the dissemination of these publications. This issue has not been a problem for MEM since 2008.”

More than a decade later, prevention is still a primary issue discussed at the airport’s annual FOD Committee meeting. Attendees include Airport Authority personnel, representatives from all airlines that operate at MEM, various airport departments, caterers and other tenants. “The committee discusses trends and ways to prevent and reduce FOD,” says Horton.

Leveraging Technology

The Airport Authority is also forging ahead with tech-based strategies. Currently, it is acquiring a new database with a geographic information system (GIS) component. “Hopefully, this new database will allow us to run more sophisticated reports to help identify trends over a period of time,” says Horton. “This information could then be shared with our tenants to ensure any problem areas are being addressed. Also, having a GIS map will allow us to easily create visual depictions of our problem areas that can then receive more focused inspections.”

Annual Safety Walk

Annual Safety Walk

A FOD database and subsequent trend analysis by the FAA and airport personnel could prove to be important steps forward. If data show that a particular FOD item keeps appearing in a particular area, MEM can take counter measures accordingly.

According to Blue, MEM’s efforts to leverage technology such as GIS reflect a larger industry trend. ”In the past, process improvement seemed to focus on more and better training for everyone involved,” he observes. “And though the attention to training programs has not dissipated in any way, lately the conversation has centered on the use of equipment and technology.”

FOD Fleet

While the Authority explores high-tech preventive measures, a mix of removal equipment continues to be the cornerstone of MEM’s front-line defense strategy. (See list below for specific products.)

Moreau explains that crews use a sweeper truck for lightweight FOD such as grass clippings, and sweeper mats for small but heavier items, such as rocks, screws and bolts.

Stuart Tozer, managing director of Aerosweep, stresses the safety benefits of his company’s FOD*BOSS tarmac sweeping equipment. Tozer notes that beyond aircraft engine damage, FOD also causes an alarming amount of damage to aircraft tires. One to three FOD*BOSS airport sweepers can be towed by a car or truck to create a sweeping area up to 24 feet wide to prevent such damage, he advises.

“FOD creates an unsafe environment for crew, passengers and ground staff,” Tozer emphasizes. “Just imagine the damage a rock sucked into a spinning propeller or turbine could do, as it ricochets like a bullet into the ground crew. Operation managers are fully aware of these risks, and are looking at increasing safety, by reducing FOD at an effective cost within the airport precinct.”

Tom Rokas, Inside Sales for TYMCO Inc., notes that the nature and quantity of FOD varies greatly from airport to airport. “It really depends on the condition of the runways and taxiways,” he explains, noting that the company’s largest sweeper has a capacity of 6 cubic yards. “That is a very large amount for an airport to pick up in a day, unless they are doing some type of construction.”

Lately, Rokas has found that many airports require their construction contractors to have a sweeper truck on site during projects on or near runways, taxiways and other areas where FOD is an issue. When choosing equipment for their own fleets, airports want flexible vehicles that can sweep roads and parking lots as well as airfield pavement, he adds.

No matter what type of equipment they use or strategies they employ, MEM and other airports share a common goal of airfield safety. “It is impossible to prevent FOD completely, however we make our best effort to reduce it as much as possible,” Horton remarks. Toward that end, he suggests establishing a “safety culture” that includes regular safety meetings, newsletters, training and reward systems that encourage employees to take a proactive approach to reducing FOD.

Memphis International Airport Facts & Figures

Project: Foreign Object Debris (FOD) Control

Location: Memphis (TN) Int’l Airport

Airfield: 4 concrete runways; 18 major taxiways

Traffic: 224,000 annual operations; 9 passenger airlines (10 when Via begins service in June 2019); 4 cargo carriers

FOD Removal: 396 instances in 2018

Staff Resources: 9 Operations employees directly involved in FOD removal & prevention

Airfield Inspections: 3/day; 1/shift

Removal Equipment: FOD*BOSS, from Aerosweep Pty Ltd; Air Sweeper 600, from TYMCO.

Original article can be read here

Airfields are a critical part of the aviation industry, and ensuring they are as safe as possible is essential. One of the most effective ways to do...

When material left in traffic areas puts individuals and equipment at risk, it becomes something called foreign object debris, or FOD. Removing this...

Airports and airlines spend billions of dollars on repairing the damage from foreign object debris. Where it comes to the control and prevention of...